What Are Electrical Enclosures & Cabinets?

One of the most critical components in the world of industrial automation is electrical enclosures and cabinets. But what exactly are they, and why are they so essential? Let’s explore the purpose, types, and considerations for selecting the right electrical enclosures and cabinets in industrial settings, shedding light on their role in protecting valuable automation equipment.

What Are Electrical Enclosures & Cabinets?

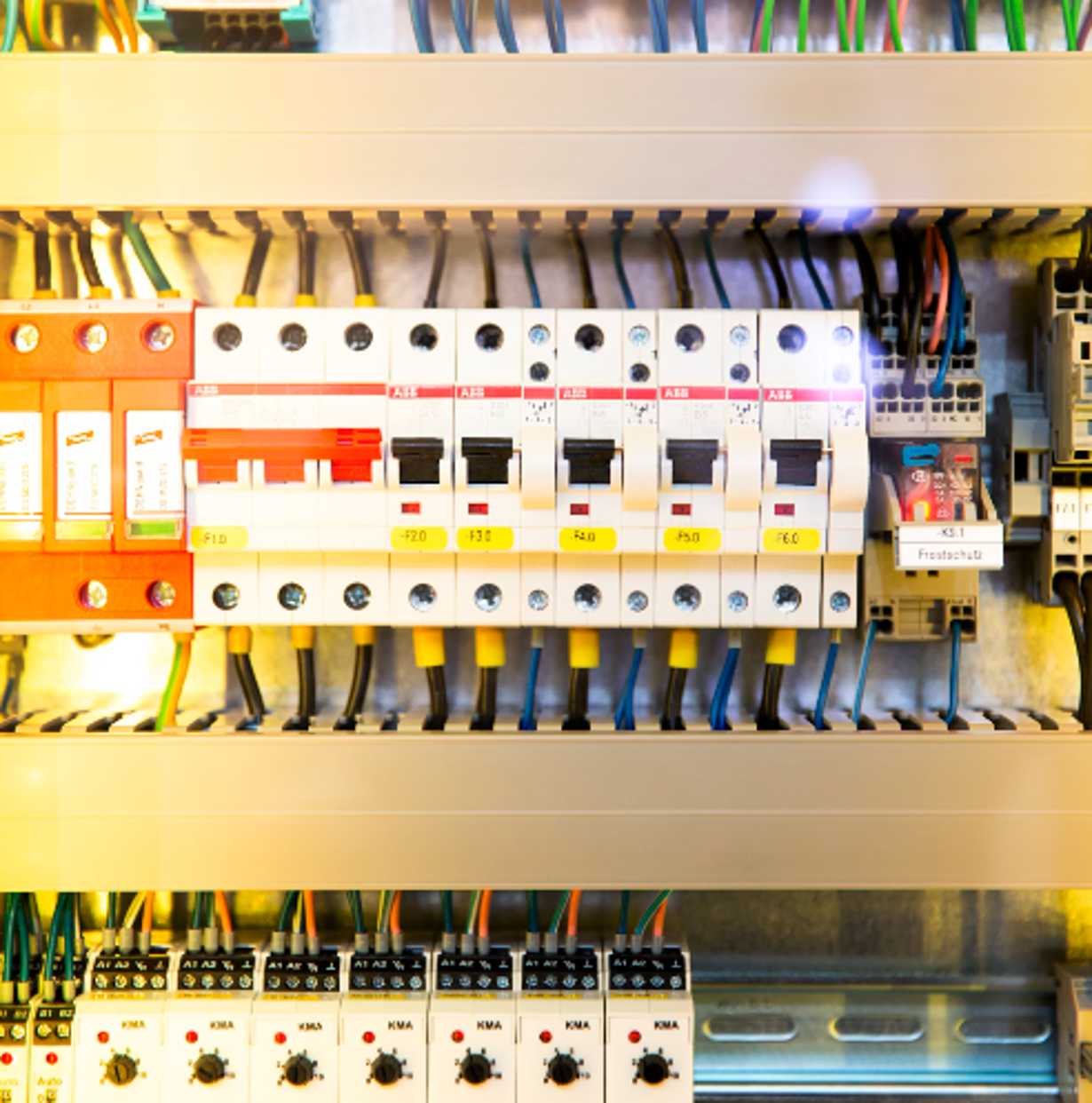

At their core, electrical enclosures and cabinets are protective cases designed to house electrical components, such as circuit breakers, switches, and other sensitive equipment.

They provide a secure environment, shielding these components from environmental hazards like dust, water, and physical damage, which can otherwise lead to system failures or downtime.

The importance of these protective housings cannot be overstated, as they ensure that electrical systems operate safely and efficiently, even in harsh industrial environments.

Also Read: Common Electrical Problems Your Building May Be Suffering From

Types of Electrical Enclosures & Cabinets

There are several types of electrical enclosures and cabinets, each designed to meet specific needs and standards:

- NEMA Enclosures: Named after the National Electrical Manufacturers Association, NEMA enclosures are categorized based on their protective qualities against various environmental factors. For instance, a NEMA 4X enclosure is corrosion-resistant and can withstand high-pressure water jets, making it ideal for outdoor or wash-down applications.

- IP Rated Enclosures: The International Protection (IP) rating system classifies enclosures based on their resistance to solids and liquids. An IP67 enclosure, for example, is dust-tight and can be submerged in water up to a certain depth, offering robust protection for sensitive electronics.

- Material-Based Enclosures: Electrical enclosures can also be categorized by the materials used in their construction, such as stainless steel, polycarbonate, or aluminum. Each material offers different benefits, like corrosion resistance, durability, and lightweight properties, allowing for customization based on the specific requirements of the application.

- Specialized Enclosures: Some industries require specialized enclosures, such as explosion-proof cabinets for hazardous environments or climate-controlled cabinets for temperature-sensitive equipment. These specialized enclosures are designed to provide additional protection against specific threats, ensuring the safety and reliability of the housed components.

Considerations for Choosing the Right Enclosure

Selecting the appropriate electrical enclosure or cabinet is crucial for ensuring the longevity and performance of automation systems. Several factors should be considered:

- Environmental Conditions: Assessing the environment where the enclosure will be used is the first step. Factors like temperature extremes, humidity, exposure to chemicals, and physical impact should guide the selection process.

- Size and Space Requirements: The enclosure must accommodate all necessary components without overcrowding, allowing for proper ventilation and easy maintenance access.

- Compliance and Standards: Depending on the industry, specific standards and certifications may be required, such as NEMA or IP ratings, to meet safety and regulatory requirements.

- Future Expansion: It’s wise to consider potential future upgrades or expansions, ensuring the enclosure can accommodate additional components without requiring a complete overhaul.

In industrial automation, the choice of electrical enclosures and cabinets is far from trivial. These protective housings are vital in safeguarding electronic components from environmental hazards, ensuring the smooth operation of complex systems.

By understanding the various types and factors involved in selecting the right enclosure, businesses can enhance the reliability and longevity of their automation equipment.

As the industry continues to evolve, staying informed about the latest advancements in enclosure technology will be key to maintaining a competitive edge and ensuring operational excellence.

Also Read: 8 Different Profitable Production Businesses That You Can Start

Visit Quotebeam to discover the latest in electrical enclosures and cabinets designed to meet your industrial automation needs.